Pipe ea tšepe ke sekoti se selelele sa tšepe, se sebelisoang haholo e le phaephe ea ho tsamaisa maro a kang oli, khase ea tlhaho, metsi, khase, mouoane, joalo-joalo. e ts'oanang, kahoo e boetse e sebelisoa haholo Ho sebelisoa ha ho etsoa likarolo tsa mechine le mehaho ea boenjiniere.E boetse e sebelisoa ka tloaelo ho hlahisa libetsa tse fapaneng tse tloaelehileng, libarele, likhetla, joalo-joalo. bolelele ba limithara tse 6.Ts'ebetso ea tlhahiso ea phala ea tšepe e entsoeng ka tšepe e bonolo, katleho ea tlhahiso e phahame, ho na le mefuta e mengata le litlhaloso, 'me matsete a thepa a nyenyane, empa matla a kakaretso a tlase ho feta a phala ea tšepe e se nang moeli.

Liphaephe tsa tšepe tse cheselitsoeng

E arotsoe ka mokhoa oa tlhahiso

(1) Ho ea ka mokhoa - arc welded pipe, ho hanyetsa welded pipe (high frequency, low frequency), khase welded pipe, sebopi tjheseletsa phala.

(2) Ho ea ka weld - ho otlolohile seam welded phala, spiral welded phala

E arotsoe ka sebopeho sa karolo

(1) Liphaephe tse bonolo tsa tšepe tse tšelang likarolo—lipeipi tsa tšepe tse chitja, lipeipi tsa tšepe tse lisekoere, lipeipi tsa tšepe tse oval, lipeipi tsa tšepe tse khutlo-tharo, lipeipi tsa tšepe tse mahlakore a tšeletseng, lipeipi tsa tšepe tse rhombus, lipeipi tsa tšepe tse khutlonnetsepa, lisekoere tsa tšepe tse sekae, tse ling.

(2) Lipeipi tsa tšepe tse rarahaneng tse nang le mahlakore a mabeli - lipeipi tsa tšepe tse mahlakore a mahlano tse sa lekanang, lipeipi tsa tšepe tse nang le sebōpeho sa petal tse hlano, lipeipi tsa tšepe tse nang le mahlakore a mabeli, lipeipi tsa tšepe tse nang le lipeipi tse peli, lipeipi tsa tšepe tse bōpehileng joaloka mahapu, lipeipi tsa tšepe tse kholo, lipeipi tsa masenke; liphaephe tsa tšepe tsa nyeoe, joalo-joalo.

Ho ea ka botenya ba lerako, e ka aroloa ka: phala ea tšepe e nang le marako a tšesaane le phala ea tšepe e teteaneng;

Ho ea ka sebōpeho sa ho qetela, e ka aroloa ka: phala e pota-potileng welded le e khethehileng-e bōpehileng joaloka (lisekoere, sephara, joalo-joalo) welded pipe;

Ho arola ka sepheo

Peipi e kentsoeng ka kakaretso, peipi e kentsoeng ka masenke, peipi e tšetsoeng ka oksijene, phala ea terata, peipi e cheselitsoeng ka metric, peipi e sa sebetseng, peipi ea pompo e tebileng, peipi ea koloi, peipi ea transfoma, phala ea motlakase e kentsoeng ka lebota le tšesaane, phala ea motlakase e entsoeng ka sebopeho se ikhethileng peipi le spiral welded pipe.

Sepheo se seholo

E sebelisoa haholo boenjiniere ba phepelo ea metsi, indasteri ea petrochemical, indasteri ea lik'hemik'hale, indasteri ea matla a motlakase, nosetso ea temo le kaho ea litoropo.Ke e 'ngoe ea lihlahisoa tsa bohlokoa tse mashome a mabeli tse entsoeng ke naha ea rona.

E sebelisetsoa ho tsamaisa metsi: phepelo ea metsi le drainage.Bakeng sa lipalangoang tsa khase: khase, mouoane, khase ea peterole e qhibilihisitsoeng.

Bakeng sa merero ea meralo: joalo ka liphaephe tse bokellang, joalo ka marokho;liphaephe tsa boema-kepe, litsela, meaho ea meaho, joalo-joalo.

Liphaephe tsa tšepe tse cheselitsoeng li arotsoe ka galvanized le tse se nang galvanized ho ea ka phekolo ea holim'a phala.Liphaephe tsa tšepe tse cheselitsoeng li ka aroloa ka mefuta e 'meli ha li tloha fekthering: e' ngoe e kenngoa qetellong ea phala, 'me e' ngoe ha e na khoele qetellong ea phala.Bakeng sa liphaephe tsa tšepe tse cheselitsoeng tse nang le likhoele lipheletsong tsa liphaephe, bolelele ba phala e 'ngoe le e' ngoe ke 4-9m, 'me bakeng sa liphaephe tse entsoeng ka tšepe tse se nang likhoele, bolelele ba phala ka' ngoe ke 4-12m.

Liphaephe tsa tšepe tse cheselitsoeng li arotsoe ka liphaephe tsa tšepe tse nang le marako a tšesaane, liphaephe tsa tšepe tse teteaneng le lipeipi tse tloaelehileng tsa tšepe ho ea ka botenya ba lerako la phala.Liphaephe tse tloaelehileng tsa tšepe ke tsona tse sebelisoang ka ho fetisisa liphaepheng tsa ts'ebetso, 'me khatello ea bona ea teko ke 2.0MPa.Khatello ea teko ea phala ea tšepe e teteaneng ke 3.0MPa.

Ho na le mekhoa e mengata ea ho hokahanya bakeng sa liphaephe tsa tšepe tse cheselitsoeng, ho kenyelletsa le khokahanyo ea khoele, khokahanyo ea flange le welding.Khokahano ea flange e arotsoe ka khokahanyo ea li-flange le khokahanyo ea welding ea flange, 'me mokhoa oa ho tjheseletsa o arotsoe ka tjheseletsa ea khase le welding ea arc.

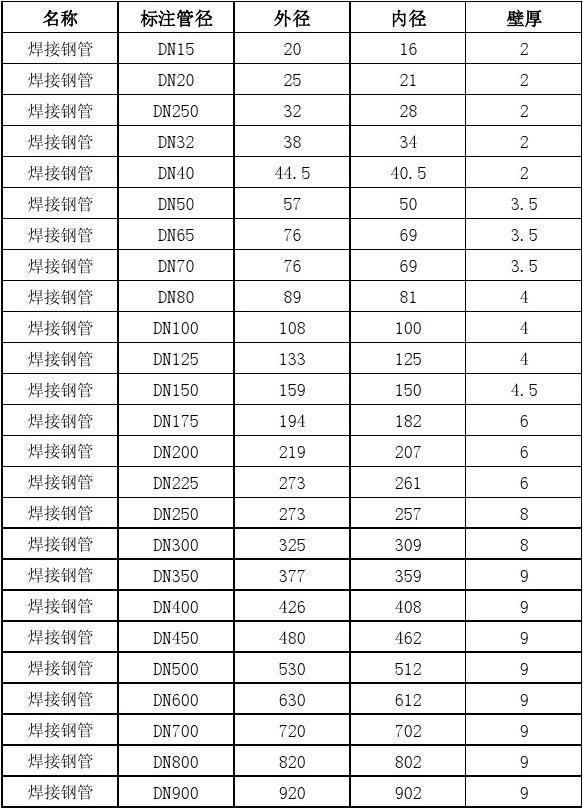

Ka tloaelo ho sebelisoa welded tšepe phala tlhaloso mefuta e fapaneng: bophara ka lebitso 6 ~ 150mm

Lipeipi tsa tšepe tse cheselitsoeng li ka aroloa ka mekhahlelo e meraro ho latela mokhoa oa ho etsa:

1. Motlakase ho hanyetsa welded tšepe pipe

Motlakase ho hanyetsa tjheseletsa phala ea tšepe, lebitso la Senyesemane ERW (Motlakase oa ho hanyetsa welded Pipe), mofuta oa weld o otlolohile seam.The resistance welding e amohela mokhoa oa ho tjheseletsa khatello ntle le tšepe ea ho tlatsa.Ha ho na ho tlatsoa ha likarolo tse ling ka har'a seam weld.Phello ea letlalo le phello e haufi ea maqhubu a phahameng a maqhubu a hona joale a etsa hore moeli oa poleiti o futhumale hang-hang ho mocheso oa tjheseletsa, 'me ho qhekella ho thehoa ka ho penya extrusion roller.Tishu e cheseletsa.

Resistance welded tšepe phala ka aroloa ka mekhahlelo e 'meli: phahameng maqhubu a ho hanyetsa tjheseletsa HFW (High maqhubu welded phala) le tlaase maqhubu khanyetso tjheseletsa tjheseletsa LFW (Low maqhubu tjheseletsa).

Lipeipi tsa tšepe tsa ERW li sebelisoa haholo-holo ho tsamaisa mouoane le lintho tse metsi tse kang oli le khase ea tlhaho, 'me li ka finyella litlhoko tse sa tšoaneng tsa khatello e phahameng le e tlaase.Hona joale, ba na le boemo ba bohlokoa lefapheng la lipeipi tsa lipalangoang lefatšeng.

2. Spiral welded steel pipe

Spiral welded steel pipe, lebitso la Senyesemane SSAW (Spiral submerged-arc welding pipe), mofuta oa weld ke seam spiral.Mokhoa oa ho kenya li-arc welding o amoheloa, 'me likarolo tse peli tse ka hare le tse ka ntle li kenngoa.Ho tjheseletsa arc ka tlas'a metsi (ho kenyeletsoa ka holim'a metsi a ka tlas'a metsi le electroslag surfacing, joalo-joalo) ke mokhoa oa bohlokoa oa ho tjheseletsa, o nang le melemo ea boleng bo tsitsitseng ba ho tjheseletsa, tlhahiso e phahameng ea welding, ha ho khanya ea arc le mosi o monyenyane le lerōle.

Pipe e nang le spiral welded e na le bophara bo boholo, bo ka fihlang ho feta 3000mm, 'me e loketse haholoanyane bakeng sa lipalangoang tsa liphaephe tsa bophara bo boholo le mehaho ea mohaho.

E meraro, e otlolohileng seam welded tšepe pipe

Pipe e Longitudinally Submerged Arc Welded, lebitso la Senyesemane ke LSAW (Longitudinally Submerged Arc Welded Pipe), 'me mofuta oa weld o otlolohile.Mokhoa oa ho tjheseletsa arc ka tlas'a metsi o boetse o sebelisoa, 'me likarolo tse peli tse ka hare le tse ka ntle li kenngoa.Botenya ba lebota la phaephe ea tšepe ea seam e otlolohileng e batla e le khōlō, 'me tšebeliso ea eona e tšoana le ea pipe ea tšepe e entsoeng ka spiral welded.

Ho latela mekhoa e fapaneng ea ho theha, liphaephe tsa tšepe tse otlolohileng tsa seam seam li ka aroloa ka mekhahlelo e 'meli: UOE (Uing le Oing forming pipe) le JCOE (J-ing, C-ing le O-ing pipe).Mokhoa oa ho etsa UOE (U theha, O ho etsa, katoloso ea bophara ba E), mokhoa oa ho etsa JCOE (poleiti ea tšepe e hatelloa ka sebopeho sa J, ebe e hatelloa ho sebopeho sa C le sebopeho sa O ka ho latellana, ebe se atolosoa).

Re lokela ho hlokomela hore submerged arc welding process (SAW) ke mofuta oa tjheseletsa fusion ea motlakase (EFW Electric Fusion Welded Pipe), e leng ho kopanya tšepe ka ho futhumatsa tšepe pakeng tsa li-electrode tse le 'ngoe kapa tse' maloa tse ka sebelisoang le workpiece.E 'ngoe ea mekhoa eo arc e qhibilihisang tšepe ka ho feletseng le thepa ea ho tlatsa ntle le khatello,' me karolo ea tšepe ea ho tlatsa e tsoa ho li-electrode.

Nako ea poso: Jan-06-2023